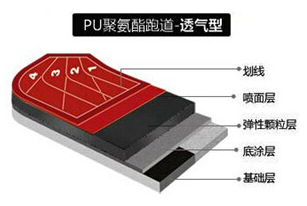

| Spraying compound running track is imported from abroad advanced technology, through specialization, has become popular in our country school track and field stadium Type:Spraying compound Color: Red, Green, Blue Thickness:13mm Basement: Asphalt; Cement Lifetime: over 8 years |

APPLICATION RANGE:

Suitable for formal athletics, general competitive game;Suitable for all kinds of school field and region( with Climate conditions in minus 16 degrees Celsius above), but not for cold ice region.Character:

| 1. Chemical stability EPDM granules could be used for kinds of difficult weather condition, with chemical stability, ozone aging and thermal oxidative aging character. 2. Good elastic EPDM granules could keep the good elastic even under the condition of low temperature. Construction technique 3. Vivid colors All pigment materials which used for our epdm granules are imported from famous company, colors of epdm granules could keep long time, with strong grey scale and uv stability. 4. Good cohession With many times of experiments and testing, our epdm granules could be mixed with pu binder totally with good cohession. |  |

Construction technique

When finished the installation of paving machine, keep the rubber floor away from the damage. About 24 hours later, when it cured, the flexible level of rubber floor is finished.

3. EPDM level installation points

Mix the binder with colored EPDM granules by standard proportion, and mix the materials totally by mix machine. Install the rubber floor by spraying machine. When finished the installation of spraying machine, keep the rubber floor away from the damage. About 24 hours later, when it cured, the EPDM sparing level is finished.