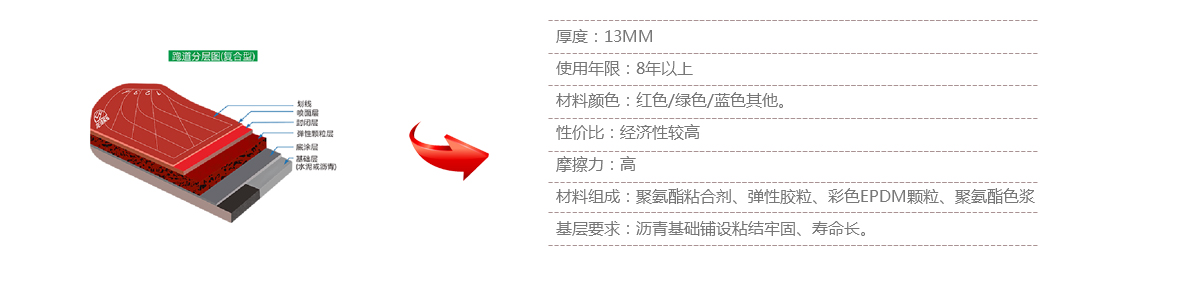

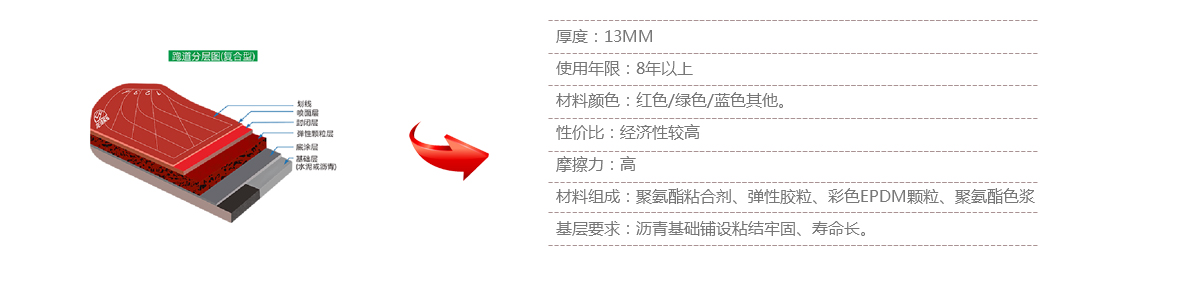

| There are two layers rubber for the composite track. The base layer is elastic buffer layer made by paving equipment with the mixed elastic rubber and polyurethane adhesive and total thickness about 10mm. The surface layer is 2-3mm thick polyurethane glue with sprayed EPDM granules as the wear layer.

|

Plastic runway material national standards(GB/T14833-93)

Item

| Indicator

|

Hardness

| 45~60

|

| Tensile Strength | 0.7 |

Elongation at break

| 90

|

Compression recovery rate

| 95

|

Rebound Values

| 20

|

Flame retardancy

| 1

|

Product Characteristic

The base layer of composite track is environment friendly product which composed of component adhesives and resilient rubber granules. Its great breathable ability can let the steam from foundation spreading more easily without steam pressure even though the high temperature. So it can meet the professional requirements and good elasticity for the runway without bubbling.

The surface layer paved with EPDM granules which have excellent UV resistance. Practice has proved that, it can be used more than 10 years without color fading.

Its strong wear ability can maintain an excellent state over 10 years even thousands of students use 10 hours everyday. The mixed EPDM granules, polyurethane slurry surface layer constructed with spraying machine. Excellent weather resistance, not easy to aging. Elastic stability, elastic and no difference between the four seasons, never winter hard summer soft. Return and suction force force strong, stressed that the overall performance of the runway, to adapt to the project and training etc.. Line is not easy to paint, bright color, do not fade, wear resistance better. Flatness reach the IAAF standard, the treatment is good, rain day without having to stop the game, the game can immediately after heavy rain, there will be no water phenomenon.